News

Revealing the entire professional product packaging process

How does the application of the product packaging process contribute to the specialisation of the production process? That is a difficult problem that businesses are looking for an answer to. To learn about the simple and professional packaging process, let’s find out details with Gumato through the following article!

- Why is product packaging necessary?

Product packaging contributes to reinforcing, containing products and protecting products from external and environmental influences, such as air, moisture, light, .. and impact by damage. damaged, deformed.

Products are carefully and carefully packed to ensure quality when reaching distributors and consumers. Packaging and packaging also show the business’s professionalism and contribute to the communication and brand positioning of the manufacturer.

In addition, the application of the product packaging process helps to simplify the process of production, packaging and transportation. Save time and capacity in the production process.

- General regulations on the packaging of goods

When packing goods and putting them into shipping standard product packaging process, it is necessary to meet some general regulations as follows:

Parcels, and shipping goods need to be carefully packed and carefully listed by the production facility. At the same time, it should contain full information from the sender, receiver, and type of item.

Containers must have enough strength and rigidity to withstand the impacts of the environment and the forces of other boxes and parcels when stacked on top of each other.

If the box is empty, make sure to use bubble paper, newspaper or foam to fill the empty space to prevent the goods from being bumped and damaged during transportation.

For items that cannot come into contact with water or steam, it is necessary to have a plastic bag to ensure that the goods are safe to avoid force majeure events.

- Professional product packaging process

3.1 The most standard product packaging process steps

The product packaging process includes the following steps:

Step 1: After the product is affixed with all kinds of quality stamps, information stamps or warranty stamps, use 3 layers of airbags to wrap the goods. To protect goods, avoid collisions and damage to goods with a maximum height of 5m.

Wrapping goods with airbags is an indispensable product packaging process.

Step 2: Use the carton to pack the wrapped products and insert the insert paper, and air foam film into the space to create a second layer of protection for the goods. Choose good quality and strong bearing cartons to protect the goods better.

Use cartons to pack products.

Step 3: The final step in the product packaging process is to paste the sender and recipient information on the top of the box. If you are more careful, you can give more information about the item so that the shipping unit can understand the product properties and handle it better during transportation.

Hướng dẫn đóng gói sản phẩm

3.2. Documents that need to be pasted on the goods

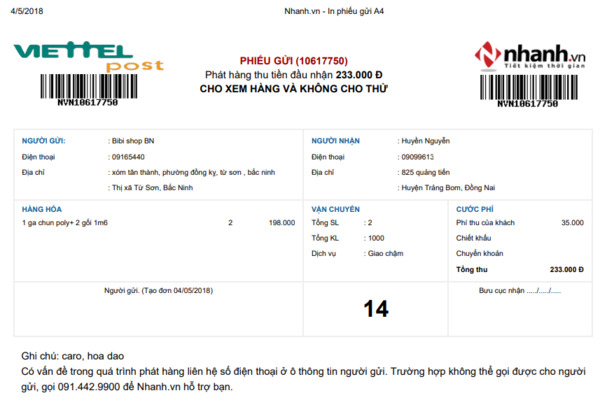

The final step of the product packaging process is to paste the shipping information on the parcel. Usually, each carrier has its delivery note template.

However, the basic delivery note has the following information: Sender information, recipient information, post-packaging weight, bill of lading code and possibly more item information.

Delivery notes usually have 2 boards, 1 copy to stick on the package so that the forwarder can check and 1 copy for the delivery person to keep as a receipt.

3.3. What should be noted in the product packaging process

Based on the product packaging process and the cost of packing goods, manufacturers and transporters need to note the following:

- Do not use damaged, punctured or used cartons and cartons. It is necessary to buy quality cartons with their brand design to increase brand recognition.

- Choose cartons such that the size of the product must contain at least 80% of the carton size.

- When packing goods, do not use old plastic bags or poor-quality plastic bags. It is necessary to use rectangular plastic bags with a uniform colour, except for black.

- Use only new, high-adhesive packaging tapes, available in either clear or yellow. When applying the tape, care should be taken not to cover the information on the shipping stamp.

- Goods need to be packed full of bubble bags, paper inserts, and bubble film so as not to break or make no noise during transportation.